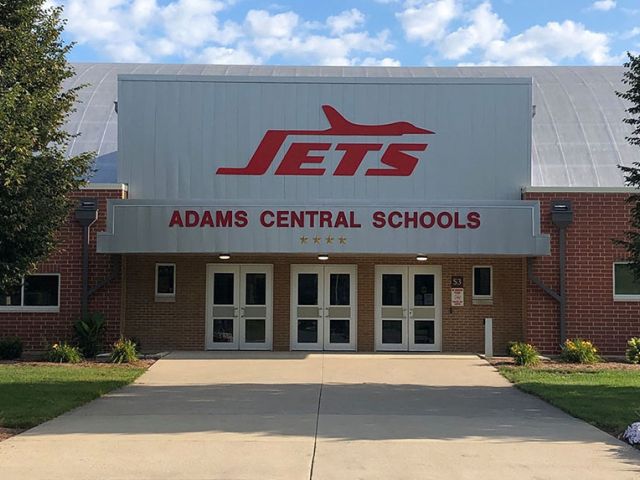

Sports, Adams Central, Bellmont

Sports, Adams Central, Bellmont

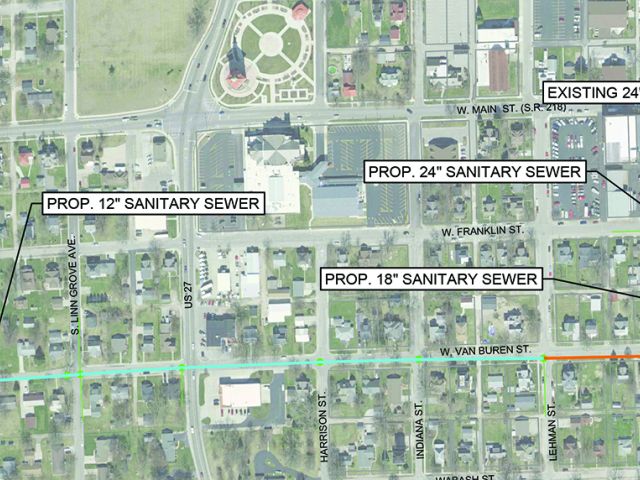

News

News

News

News

News

News

News

News

News

News

Sports, South Adams

Sports, South Adams

News

News

News

News

News

News

News

News

News

News